Provide you with the latest enterprise and industry news.

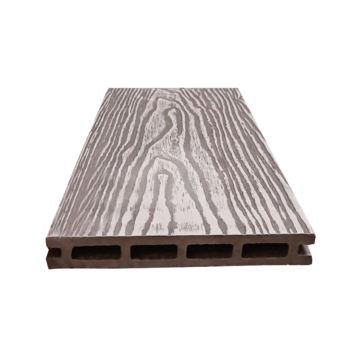

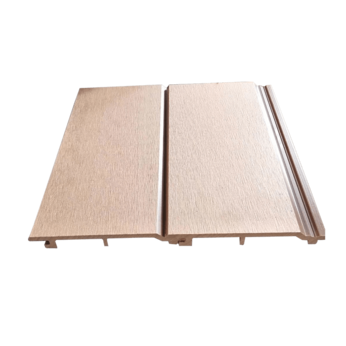

Printing Technology: High-definition digital printing technology is used to apply wood grain patterns and colors onto the vinyl surface. This technology ensures precise and detailed replication of various wood species, knots, and grains.

Wear Layer: A wear layer is applied on top of the printed surface to protect the flooring from scratches, stains, and fading. The wear layer is typically made of clear PVC or polyurethane and is available in different thicknesses depending on the flooring's intended use and durability requirements.

Surface Coatings: Some plastic wood flooring products may have additional surface coatings or treatments, such as UV coatings. UV coatings protect the flooring from harmful ultraviolet (UV) rays, preventing color fading and maintaining the flooring's appearance over time, especially in areas exposed to sunlight.

Anti-Slip Properties: For safety in areas prone to moisture, some plastic wood flooring may have anti-slip properties applied to the surface. This helps reduce the risk of slipping and enhances the flooring's suitability for wet or humid environments.

Stain Resistance: Certain surface treatments provide stain-resistant properties, making it easier to clean and maintain the flooring's appearance.

Anti-Scratch Properties: Some flooring products are designed with enhanced scratch resistance to withstand the wear and tear of daily use.

Anti-Microbial Treatments: In environments where hygiene is critical, such as healthcare facilities or commercial spaces, anti-microbial treatments may be applied to inhibit the growth of bacteria and molds on the flooring surface.

Sound Absorption: Some plastic wood flooring products have surface treatments that enhance sound absorption, reducing noise levels and creating a quieter environment.

Texture Variety: Manufacturers may offer different texture options, such as smooth, distressed, or hand-scraped finishes, to cater to various design preferences and styles.

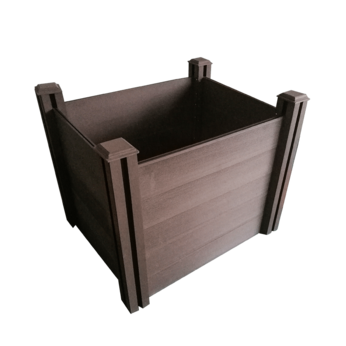

The combination of these special treatments contributes to the attractiveness, performance, and durability of plastic wood flooring. When choosing a plastic wood flooring product, it's essential to consider the surface treatments applied, as they can significantly impact the flooring's suitability for specific applications and environments.

English

English Español

Español