Provide you with the latest enterprise and industry news.

Selecting the right raw materials for plastic wood flooring is crucial to ensure the final product's quality, appearance, and performance. Here are the key steps to make a well-informed raw material selection for plastic wood flooring:

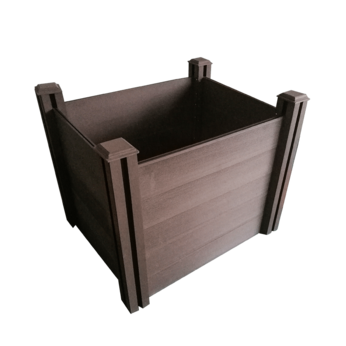

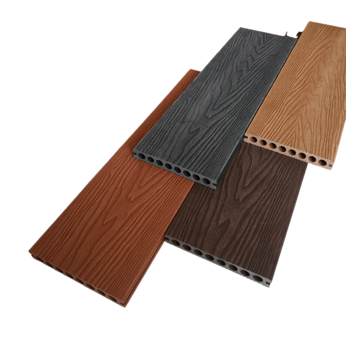

Define Product Requirements: Clearly define the specific requirements and characteristics you want for the plastic wood flooring. Consider factors such as the desired wood grain pattern, color options, thickness, wear layer, and overall performance attributes.

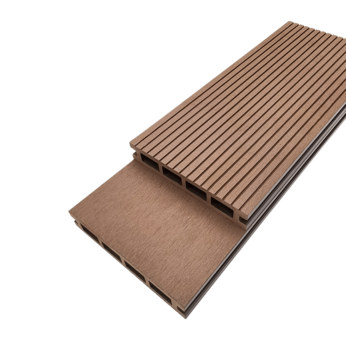

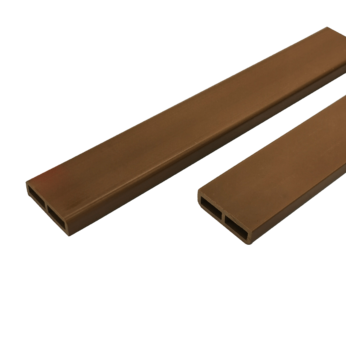

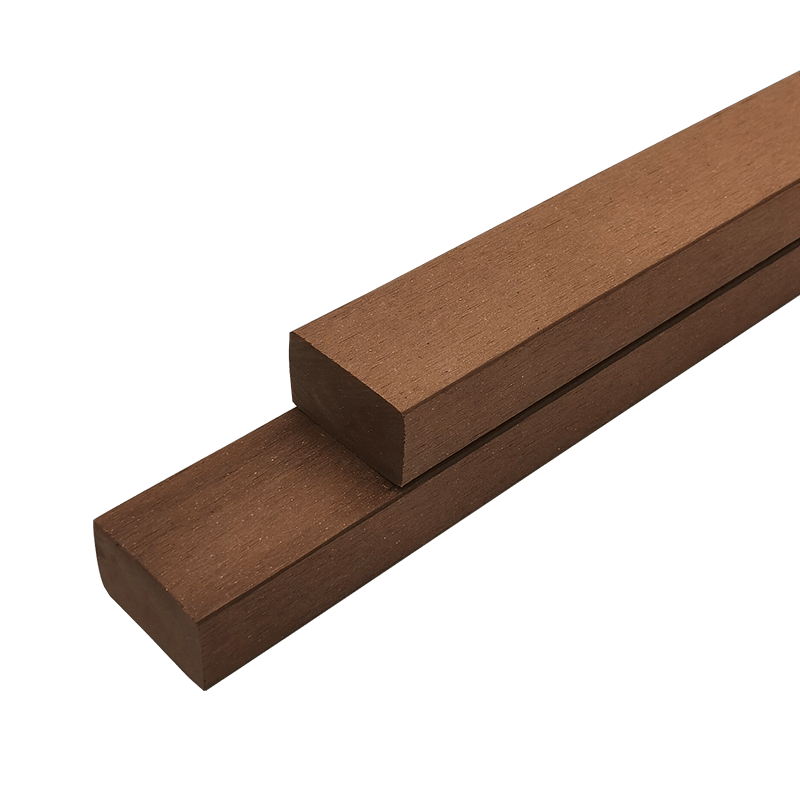

Choose Base Material: The base material for plastic wood flooring is typically PVC (polyvinyl chloride) or other vinyl compounds. Evaluate the properties of different vinyl materials, including their durability, flexibility, and stability, to select the most suitable base material for your flooring.

Additives and Stabilizers: Determine the necessary additives and stabilizers to enhance the vinyl material's performance and longevity. Common additives include plasticizers, UV stabilizers, and antimicrobial agents.

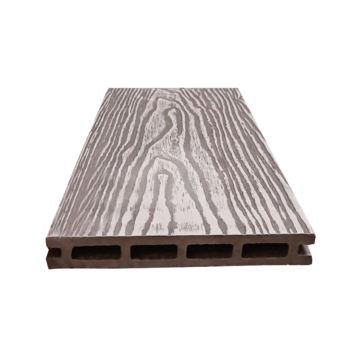

Pigments and Colorants: Select the appropriate pigments and colorants to achieve the desired wood-like colors and patterns. High-quality colorants are essential for achieving realistic and long-lasting coloration.

Printing Technology: Choose the printing technology to replicate wood grain patterns onto the vinyl surface. High-definition digital printing is commonly used for its accuracy and versatility in creating realistic wood looks.

Embossing Process: If an embossed texture is desired, consider the embossing process and select the appropriate embossing patterns to achieve the desired surface texture.

Backing Material: Evaluate the available backing materials that provide stability and insulation properties to the flooring. Common options include cork or foam backing.

Wear Layer: Determine the type and thickness of the wear layer that will provide protection against wear, scratches, and stains. High-quality wear layers are essential for ensuring the flooring's durability.

Environmental Considerations: Take into account the environmental impact of the raw materials chosen. Consider using eco-friendly and recyclable materials to align with sustainable practices.

Certifications and Standards: Ensure that the chosen raw materials comply with industry standards, regulations, and certifications for safety and quality.

Supplier and Quality Assurance: Work with reputable suppliers and manufacturers who can provide consistent and high-quality raw materials. Perform quality assurance checks on the raw materials to ensure they meet the specified criteria.

Cost Analysis: Conduct a cost analysis to balance the desired quality and performance attributes with the budget constraints.

By carefully considering these factors and conducting thorough research, you can make informed decisions during the raw material selection process for plastic wood flooring. Choosing the right raw materials is crucial to producing a high-quality and aesthetically appealing product that meets customer expectations and industry standards.

English

English Español

Español